Two more feet, and I can fit it in the fridge.

– Homer Simpson

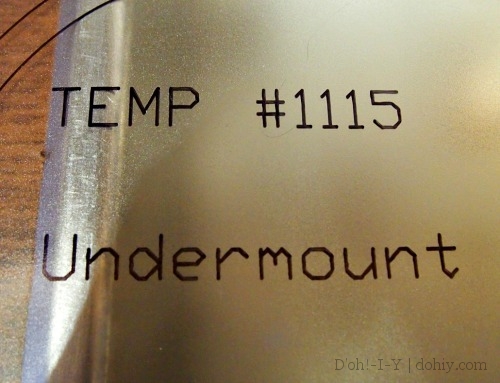

When we ordered our quartz, the kitchen person told us to await templates that we could roll out over our existing counters to check our measurements. Yesterday, they arrived!

The templates are vinyl sheets cut to size with all the edges and cuts shown in place. I was weirdly delighted that all the information had been hand-lettered by a draftsperson rather than machine printed or scrawled.

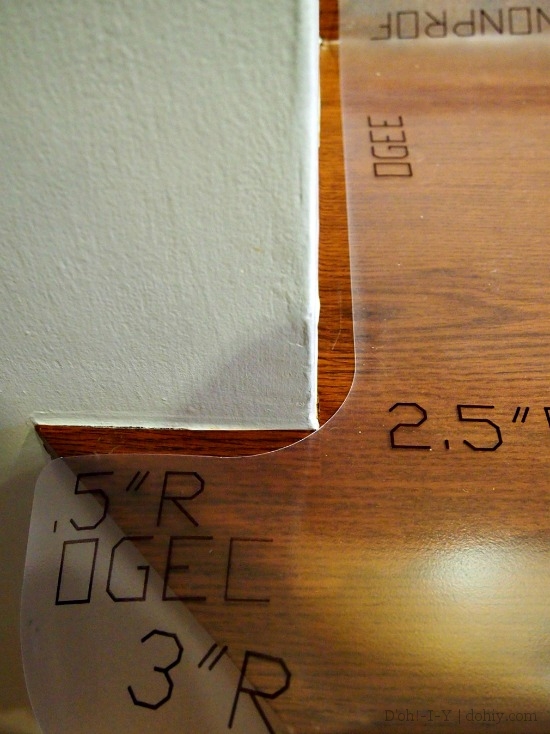

Rolling out the templates accurately was a little tricky because we currently have a 4-inch backsplash that the new surface will not.

For both obstacles, we push the template up as far as possible and checked the offset, then floated the pattern pieces over the top and eyeballed everything again.

By the way, “OGEE” on the templates refers to the edge we ordered for the front of the counters. It’s a routed edge, while the edges at the ends and against the walls will be flat.

Ogee edge from the Riverstone quartz site

We have three countertop areas. Two of the three checked out just fine. But something was lost in translation on the third.

If there is a problem with the templates, you take them back to Menards, where they will correct the order. The measurements for this piece were right, but we didn’t love the idea of an ogee edge and inside radius up against the wall. So it was back to Menards!

It turned out that the piece had been entered correctly in the system, but the template-maker got it wrong on the vinyl. I imagine it must have really seemed like an unlikely piece to the fabricator! Kev printed off a photo of the weird corner, and the department manager will fax that over on Monday.

The angle goof is a bit of a frustrating setback, but I’m glad we found out now. The template is an option that the buyer can delete from the order, but it’s less than $40 and completely worth it. If this finished piece arrived with an inside radius corner and the wrong edge, we’d have a situation of high vexation. Plus, it was really useful to check our measurements with something tangible–it would have been easy to make a mistake at our end.

We’re getting there! If the change can be made by fax, we are looking at April delivery.

5 Responses to DIY Quartz: Checking the Measurements